Competition Bushing Neck 3 Die set

Competition Bushing Neck 3 Die set

Now anyone with a standard reloading press can benefit from advanced benchrest techniques.

This may be as much as .008″ – .010″ smaller than the maximum cartridge dimensions typically shown in most reloading manuals.

Since the majority of cases that the reloader is likely to encounter in the field are thicker than the minimum specifications that the dies were designed for, case necks are often resized excessively.

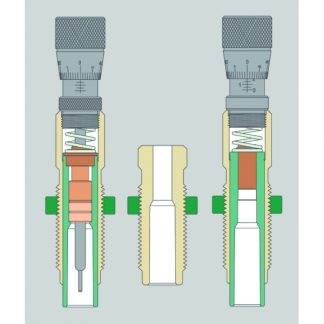

It can be easily demonstrated that excessive resizing of the cartridge case quickly leads to stress distortion and concentricity problems. The new Type S – Bushing Style Dies offer a simple solution to this age old problem

Products

Showing all 5 results

Showing all 5 results