The founding fathers and the brave men who fought the American Revolution were often forced to melt down scrap pieces of lead and forge their own rounds just to be able to survive.

Those same values are what derive a modern reloader to craft their own ammunition today. So, to keep you on that path, here are our 5 best tips and tricks about reloading for both beginners and experts alike.

-

The Size of Your Workspace Doesn’t Matter

Space in your home comes at a premium. Some are blessed with large basements and buildings where square footage is no object. Others may only have a studio apartment. Thankfully reloading doesn’t require a large amount of space.

A reloading bench only needs to be large enough to fit the essentials and wide enough for you to sit behind it. Don’t let a lack of space be the reason you don’t pursue reloading. -

Use a Single Stage Press

One of the biggest mistakes made by beginners is the drive to go out and buy the biggest, the best, and the most expensive equipment on the market. This is akin to buying a Ferrari before you learn to drive.

A single stage press can handle all your needs as a beginner, and it’s a great place to start your journey. Even experts benefit from these simple presses with many turning to them for high precision loads. -

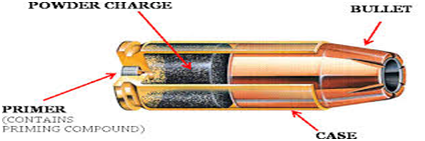

The Scale is Very Important

When it comes to reloading supplies, the scale for powder measure is the most important component. This is a piece of equipment where quality and price matters. Spend the money to get a high-quality scale. There is no point in the reloading process where you should be as precise as when measuring your powder load.

Too much, and you have a hot round capable of inflicting damage to both you and the firearm.

Too little, and you end up with weak loads that will greatly affect your accuracy, range, and efficiency. -

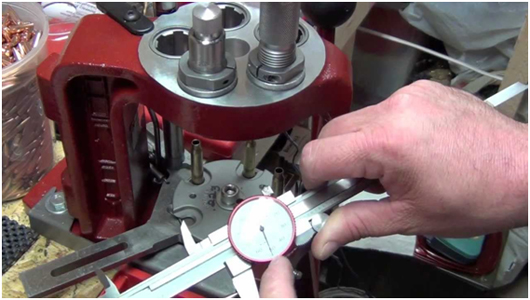

Cartridge Gauges

Nothing will infuriate a firearms enthusiast like rounds that fail to load, fire or eject. In the world of semi-automatics, this is an ever-present threat.

These handy little tools will ensure that your cartridges are within the extremely tight margins that semi-autos commands to routinely load, fire and eject.

Even for those of you reloading revolver rounds, ensuring tolerance shouldn’t be an afterthought. Revolvers are more likely to chamber and fire a round that isn’t within specs, but you should be striving for perfection, and that means gauging your rounds. -

Ask for Help

People that reach the top of their fields all get there with help and coaching. Regardless of your skill level, do not be afraid to ask for help or a second opinion. The only way to further your reloading expertise is with practice and help from others.

Reloading supplies can be a maze of products, terminology, and techniques; therefore the expert staff at Titan Reloading is always ready to help.To learn more or inquiries about the multitude of reloading products we carry please visit www.TitanReloading.com or contact us at 262.397.8819.