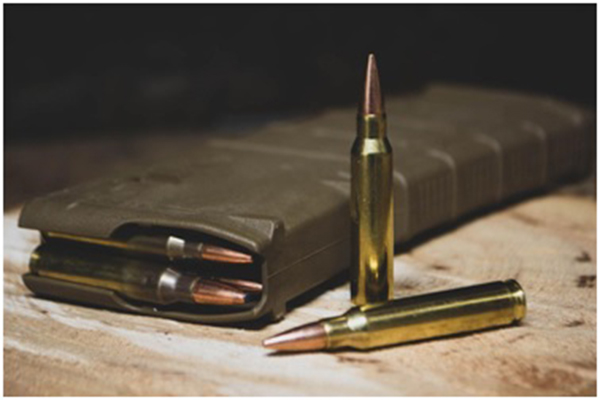

Reloading ammunition isn’t just about saving money; it’s a rewarding process that allows you to fine-tune your ammo for optimum performance and accuracy. To simplify your journey and help you make informed decisions, here are five must-have reloading supplies to help you get started building ammunition that suits your shooting style.

1. Case Trimmers

Case trimmers are essential for any gun enthusiast who reloads their own ammunition. These bench-mounted devices allow you to trim the casings of your spent cartridges quickly and accurately, correcting the length, and ensuring they will properly fit in your firearm’s chamber.

When selecting a case trimmer, consider factors such as ease of adjustment, durability, and compatibility with different cartridge types. By investing in a high-quality case trimmer, you can ensure consistent performance with greater accuracy.

2. Bullet Pullers

Bullet pullers are another must-have for anyone looking to reload their ammunition. These tools help remove bullets from the cartridge case without damaging them, making it easier to correct reloading mistakes and avoid misfires.

When shopping for bullet pullers, cheaper options may save you money upfront but can cost more in the long run due to frequent replacements. Look for brands that offer durable materials like aluminum or steel construction. Thus, you’ll enjoy safe, accurate shooting experiences while saving money on ammunition costs.

3. Case Gauges

Investing in a reliable case gauge should be essential to any gun enthusiast’s toolkit for safe and efficient reloading. A case gauge helps ensure that your ammunition meets the necessary dimensions for proper operation and safety when used in your firearm.

Case gauges also allow you to check the length, diameter, and overall quality of your cases before reloading them and avoid using faulty cases. By detecting these issues early on, you can discard damaged casings before they cause dangerous malfunctions while firing.

4. Powder Tricklers

Powder tricklers are essential for precision reloading. Powder tricklers allow for the controlled dispensing of gunpowder, which can be extremely helpful in ensuring consistent and precise powder measurements.

When using a powder trickler, it’s essential to take your time and be patient. Rushing the process can lead to inconsistent charges that could affect the accuracy of your shots. With proper use and practice, a powder trickler can help you achieve reliable performance in due time.

5. Reloading Presses

Reloading presses come in various types, including single-stage, turret, and progressive presses. Single-stage presses are ideal for beginners as they allow for precision work on each round, while turret presses can handle multiple stages of the process at once and offer more efficiency than single-stage presses, and progressive presses offer even greater speed and efficiency by automating much of the reloading process.

Regardless of which type you choose, investing in a high-quality reloading press that is easy to operate is essential. With proper care and maintenance, your reloading press can provide years of reliable reloads.

Master Reloading and Achieve Superior Results with Titan Reloading

Reloading your own ammunition offers numerous benefits, including cost effectiveness and customization options that are not available with factory ammo. By utilizing the information and reloading supplies mentioned above, you can tailor your ammunition to meet specific needs, firearms, and shooting styles and achieve improved accuracy and performance.

At Titan Reloading, we understand the importance of having the right tools for your reloading needs. Hence, we’re proud to be the number one choice for reloading supplies by offering competitive pricing and a wide range of reloading supplies and equipment from all the leading brands in the industry.

Contact Titan Reloading today to learn more or visit our showroom, conveniently located at 994 W. Sumner St., Hartford, Wisconsin, to browse our extensive range of reloading supplies and ask about our Lifetime Loyalty Discount to find out how you can earn an extra discount every time you shop with us. www.TitanReloading.com