Have a Question?

August 2023

RELOAD WITH CONFIDENCE!

What’s Your TITAN Advantage?….WE RELOAD!

***Your Reloading Specialists***

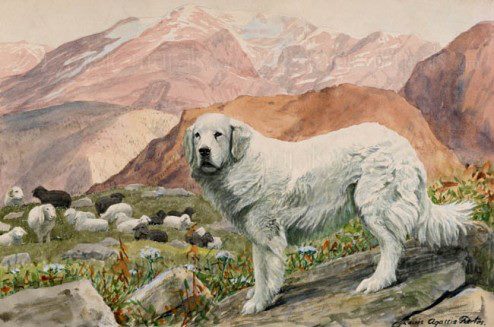

BE A SHEEPDOG

Sheep are powerless to defend against the wolf. The sheep will fall prey to any attacks on the flock by wolves. A Sheepdog spends every day blending in with the flock. Unlike the sheep, the Sheepdog has all the same abilities that the wolf does. The only difference is the wolf intends to prey on the sheep and the Sheepdog intends to protect them. BE A SHEEPDOG! Wolves beware of the Sheepdog…..you might want to rethink your career choice before it’s GAME OVER because we’re packin’ too!!

We are truly enjoying all the friends we have made through Titan Reloading and look forward to many more. Feel free to contact us. When possible, please email us rather than call. Due to our limited phone system and staff we are able to respond to your questions quicker via email. Please include your full name or order ID number with any order inquiries. Service and Support is our top priority. As always, you will find many answers to questions in the “FAQ” and “Help Videos” areas of our website www.titanreloading.com . Check us out on YouTube .

Dennis / Titan Reloading

FEATURED PRODUCT:

MEC 600 JR. MARK 5

Mayville Engineering Company, foremost manufacturer of reloading equipment in America, is widely respected for its continuing dedication to precision engineering. This precision is incorporated into every one of MEC s New Generation reloaders, rendering truly innovative and efficient engineering designs.

The MEC 600 JR. MARK 5 is no exception. The Mark 5 offers the convenience of simple, single-stage operation at an affordable price.

The Mark 5 is remarkable in that it performs each of the basic reloading steps with a mere pull on the handle- depriming, priming, resizing the metal base, measuring the correct amount of powder, firmly seating the wad column, measuring the precise amount of shot and forming a tightly sealed crimp.

Every step of the reloading sequence is performed with a minimum of motion. An exclusive shell holder positions the shell at each station. No transfer die is required, and resizing dies at reconditioning and crimping station give your shell its proper form.

Several features make the MEC 600 JR. MARK 5 today s best buy:

- The Cam-actuated reconditioning station with positive ejection.

- The Adjusta-Guide wad feed device with vertical adjustment to permit rapid wad insertion.

- The new one piece Spindex crimp starter with swivel action to correctly align with the original shell creases can be changed from 6-8 pt. in seconds

- The Pro-Check which keeps the charge bar in proper sequence to prevent spilled powder or shot.

- Best of all, the crimp die is now manufactured from a revolutionary new material called DuPont Zytel which makes maintenance a breeze. The glass-reinforced strength of Dupont Zytel far exceeds any requirements, is absolutely rust free, and actively resists the build-up of residue carried into the die on fired shells. Thus, the die slides effortlessly over the casing, making a perfect crimp every time.

NOTE: This reloader will reload steel shot shells. To convert to steel shot kit #8433 is necessary. Do not use components designed for use with lead shot when loading steel shot shells.

NOTE: A special steel shot charge bar must be used when loading steel shot. Do not use charge bars designed for lead shot when loading steel shot shells.

INSIGHT OF THE MONTH:

Maintaining Your Reloading Supplies: Tips for Longevity

Whether you re a beginner or an experienced gun enthusiast, taking care of your reloading supplies is essential for optimal performance and longevity. In this article, we ll share essential maintenance tips and advanced techniques for extending the lifespan of your reloading equipment to ensure you get the most out of your reloading experience.

Maintaining your reloading supplies is an indispensable part of the equation when it comes to safeguarding your passion for shooting or hunting. This investment not only enhances your marksmanship skills but also extends the longevity of your gear.

To keep your shooting sessions seamless and your gear lasting longer, we ve assembled a helpful guide on maintaining your reloading equipment. From understanding different types of supplies to learning practical cleaning and storage techniques, here are some of the best ways to help you see significant improvements in your shooting experience.

1. Proper Storage

To ensure the longevity of your reloading equipment and supplies, it s essential to store them in a dry environment, as moisture can cause damage and corrosion to your brass and bullets, compromising their performance. Invest in airtight containers or ammo cans with moisture-absorbing packets to keep your components free from humidity.

Additionally, a well-organized system for storing your reloading supplies will make it easier to find what you need and prevent any mix-ups that could lead to dangerous mistakes. Consider using clear plastic bins or labeled drawers to separate different types of brass, bullets, and other components, as this will save you time during reloading sessions while ensuring accuracy and safety.

Furthermore, rust can be detrimental to the functionality of your reloading equipment, so taking steps to prevent its formation is crucial. After each use, thoroughly clean all metallic parts using an appropriate solvent or oil-based cleaner designed for firearms maintenance. Apply a light coat of protective oil before storing the equipment in a cool, dry place away from any potential sources of moisture.

2. Proper Cleaning

Remember that proper cleaning and maintenance of your reloading supplies improves performance and extends their lifespan. Don t overlook these essential steps in caring for your equipment.

-

Cleaning Brass Casings

After every use, make sure to remove dirt, debris, and residue from the casings. Use a brass tumbler or cleaning solution to achieve a polished finish.

-

Maintaining Dies and Presses

Keep your dies and presses clean by wiping them down with a cloth after each reloading session. Inspect for any signs of wear or damage that may affect their performance.

-

Cleaning Powder Measures

Regularly clean your powder measures using compressed air or a soft brush to ensure accurate powder measurements.

-

Lubrication

Choosing the proper lubricant is crucial for maintaining your reloading supplies. Different types of lubricants are designed for specific components, such as case bullet lube. Be sure to select a lubricant compatible with your materials and provides adequate protection against heat and friction.

Proper application techniques are essential to ensure adequate lubrication. Use a clean cloth or brush to apply a thin layer of lubricant evenly on the surfaces that require it. Avoid over-lubrication, as excess lubricant can attract dirt and debris, leading to malfunctions in your reloading process.

3. Inspection and Replacement

Regularly inspecting your reloading supplies is crucial for identifying signs of wear and tear. Look for visible damage, such as cracks, dents, or rust on press components. Pay attention to any unusual noises or reduced performance during reloading, as these can also indicate worn parts.

Regularly inspecting cases for signs of wear or damage is another crucial in maintaining the longevity of your reloading equipment. By keeping a close eye on your cases, you can ensure their integrity and avoid potential accidents. Additionally, checking primer seating depth accuracy is essential for consistent and reliable ammunition. Lastly, replacing worn-out dies will guarantee optimal performance and prevent any issues during the reloading process.

Titan Reloading One Stop Shop for All of Your Reloading Supplies

Maintaining your reloading supplies is a crucial aspect of being a responsible gun owner and ensuring optimal performance. Neglecting regular maintenance can lead to issues such as corrosion, contamination, and wear and tear, affecting the efficiency and safety of your reloading process.

At Titan Reloading we believe in the power of precision, and our vast range of premium reloading supplies is a testament to this commitment. Crafted by the leading brands in the industry, each product is meticulously designed to deliver unbeatable performance and enduring quality.

From our knowledgeable staff to competitive prices, we aim to give you an unparalleled shopping experience. Every visit is an opportunity to explore our ever-evolving selection of reloading equipment and find precisely what you need to increase your performance.

Titan Reloading 994 W. Sumner St., Hartford, WI 53027 1-262-397-8819

WE’RE SETTING THE STANDARD, ONE CUSTOMER AT A TIME.