Have a Question?

February 2015

You can subscribe to this Newsletter if you sign up for an account with Titan Reloading.

CLICK HEAR TO REGISTER AN ACCOUNT

CLICK HERE To browse an archive of past newsletters.

FEBRUARY 2015 NEWSLETTER

FEBRUARY 2015 NEWSLETTER

Well, my boxes of empty brass are all but gone already and it’s only February 1st. Hmmm….that gives me a couple months then…..to think about a new rifle to create more empty brass for next winter. Yeah….that’s it…..I’ll put this down time to good use….problem solved! Ohhh Honey…..I have a great idea….we should buy you a new rifle for this summer.

We are truly enjoying all the friends we have made through Titan Reloading. Robin and I look forward to many more. Feel free to contact us. When possible, please email us rather than call. Due to our limited phone system and staff we are able to respond to your questions quicker via email. Please include your full name or order ID number with any order inquiries. Service and Support is our top priority. As always, you will find many answers to questions in the “FAQ” and “Help Videos” areas of our website www.titanreloading.com . Check us out on Google+ and Facebook .

Dennis / Titan Reloading

FEATURED PRODUCT:

PERFECT POWDER MEASURE

Best for reloading rifle calibers.

Almost as good as a scale!

Lee didn’t invent the drum type measure — they perfected it! This measure is unique, because it solves all of the problems common to ordinary drum type measures. It is a pleasure to use, not only because it is the smoothest operating measure ever made, but you have the confidence that your charges will be the most uniform possible.

LEE PERFECT POWDER MEASURE solves all of these problems

Eliminates Cut Powder and Jerky Action

A soft elastomer wiper strikes off the metering chamber rather than cut the powder. You’ll be surprised at how smoothly the rotor operates. More importantly, you will enjoy the most uniform of charges.

Stops Drum Binding

A nylon cone shaped drum adjusted to zero clearance. The more it’s used, the more perfect the fit becomes. The nylon is self lubricating so it will never bind or wear out.

Meaningful Calibration

A micrometer adjuster that reads directly in cubic centimeters. Just multiply the charge in grains by the cc for one grain and you have the setting. So very much better than a meaningless setting as most supply.

Safer

“O”ring positively locks the adjustment and removes all end play.

Versatile

The metering chamber is the proper size for large rifle charges and the strike off opening small enough to work well with pistol size charges. The Lee Perfect Powder Measure works fine for charges from two grains to over 100 grains.

Changing Powder is Fast and Easy

Rotate the hopper 1/4 turn to shut off the powder flow and the hopper can be lifted off. You can empty the hopper from either end. The valve is also a powder baffle which contributes to the unusual accuracy of this measure.

Stops Powder Bridging

Tapered drop tube quickly passes the powder without bridging.

Automation

The very best measure ever made.

Metering Chamber: Micrometer

Includes: Micrometer adjustable

Powder Charge Thrown: 2 to over 100 grains

Material: Nylon and Aluminum

NOTE: Does not work with the Lee Powder Through Expanding Dies. The optional Universal Charging Die 90273 makes the case operate the measure. Includes adapters to fit almost all cartridges.

INSIGHT OF THE MONTH:

PERFECT POWDER MEASURE ON A TURRET PRESS

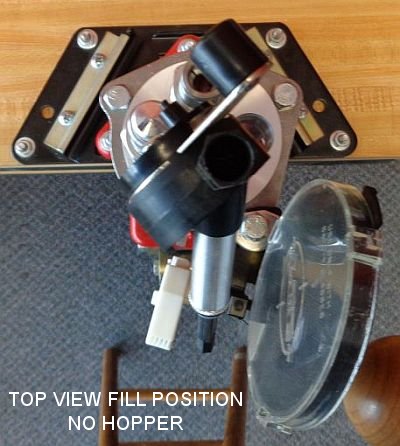

The Perfect Powder Measure is designed to charge rifle calibers that are larger than the throw capacity of the Auto Disk powder measures. It is fully automatic when mounted on a Load Master progressive press using the Universal Charging Die 90273. As a case is raised up into the die the powder measure actuates to drop a charge and as the ram is lowered the powder measure is reset to the fill position as it is attached to the press ram by means of a chain. The Perfect Powder Measure works in the exact same way on a turret press except the measure must be reset to the fill position manually. This is because the measure rotates around in the turret making it impossible to attach a chain to the ram. The powder measure must be setup on the press in only one position as shown in the following pictures. Note that in the drop and fill positions the adjustable powder vile of the powder measure is directly toward you as you stand in front of the press.

With the powder hopper removed you can see that the drum body and lever of the powder measure are located on the backside away from you at 45 degrees.

To clear the Safety Primer Feed as the turret rotates around the powder measure must remain in the drop position until the powder die rotates above the case. This is when you manually flip the lever on the powder measure and reset it to the fill position. Now raise the ram to drop the charge and leave the measure in the drop position until it comes around for the next case. The powder measure bumps the Safety Primer tray slightly as it rotates by but I like that as it jiggles the primers to prevent them from wedging against one another in the tray.