Have a Question?

August 2017

You can subscribe to this Newsletter if you sign up for an account with Titan Reloading.

CLICK HEAR TO REGISTER AN ACCOUNT

CLICK HERE To browse an archive of past newsletters.

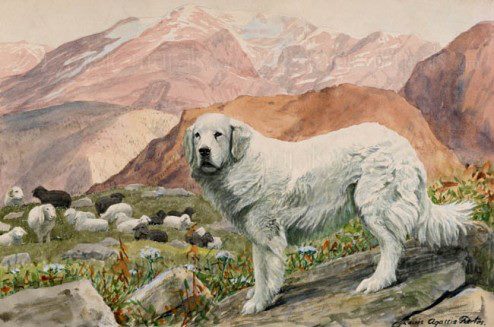

BE A SHEEPDOG

Sheep are powerless to defend against the wolf. The sheep will fall prey to any attacks on the flock by wolves. A Sheepdog spends every day blending in with the flock. Unlike the sheep, the Sheepdog has all the same abilities that the wolf does. The only difference is the wolf intends to prey on the sheep and the Sheepdog intends to protect them. BE A SHEEPDOG! Wolves beware…..we’re packin’ too…..your game is over!

We are truly enjoying all the friends we have made through Titan Reloading and look forward to many more. Feel free to contact us. When possible, please email us rather than call. Due to our limited phone system and staff we are able to respond to your questions quicker via email. Please include your full name or order ID number with any order inquiries. Service and Support is our top priority. As always, you will find many answers to questions in the “FAQ” and “Help Videos” areas of our website www.titanreloading.com . Check us out on Google + and Facebook .

Dennis / Titan Reloading

FEATURED PRODUCT:

LEE COLLET DIES

Guaranteed to load the most accurate ammunition or your money back!

There is no loading system that will load more accurate ammunition than Lee Collet Dies. Lee guarantees it in writing with every set. No one but Lee has ever dared to make a guarantee like this “Smallest group size or your money back.” A collet squeezes the case neck against a precision mandrel for a perfect fit with minimum run-out. No lube case is needed. Cases last ten times longer, so the savings on only 35 cases will pay for the dies.

Maximum accuracy is usually achieved by seating the bullet out far enough to touch or almost touch the rifling. This provides the shot start pressure normally supplied by the crimp. That’s why a dead length bullet seater is included to complete the most accurate reloading system ever made. These dies size only the neck to preserve the perfect fit of fire forming. Only reload cases that have been fired in your gun.

Not recommended for autoloaders, slide or lever action guns.

This set is designed for assembling the most accurate ammunition, but is not recommended for hunting rounds as the case is neck sized only and the bullet is not crimped in case.

Includes:

Collet Neck Sizing Die

Dead Length Bullet Seating Die

Shell Holder

Powder Measure

Charge Table

Storage Box.

INSIGHT OF THE MONTH:

Collet Die Explanation

The Collet neck sizing die is superior to the competition’s neck sizing die design because it squeezes the neck against a mandrel. This results in very uniform case mouth inner diameter, regardless of case wall thickness.

With bushing-type neck sizing dies, one has to select (and usually purchase) the appropriate bushing to get the desired case mouth inner diameter. Uniform case mouth inner diameter gives uniform bullet pull, and as you know, uniformity is what accurate ammunition is all about.

The Collet die set also includes what we call the “dead length” bullet seating die. This die is set up like a full length sizing die, in that one adjusts the die down so that the shell holder presses against the bottom of the die when the ram is at the top of its stroke. This pressure removes any clearance between the shell holder and ram, lever linkage, die threads and press frame, etc. and results in a more uniform bullet seating depth. Note that there is no provision for crimping in this die.

Collet Die Adjustment

If you are using the Collet die in an RCBS Rockchucker press, or a similar design that toggles over center at the top of the (ram) stroke, this applies far greater force than is necessary to resize just the neck of the case, and can damage the die or collapse the case. To correct this situation, adjust the die two full turns into the press after the die contacts the shell holder with the ram at the top of its stroke, rather than one as in the instructions. This will stop the press before it gets to the toggle over point. With a press without having an over center feature, apply about 25 lbs. of pressure to the handle once it bottoms out to resize the case. On most presses, this translates to over 600 lbs of pressure on the ram.

The collet might be stuck in the closed position from closing the die without a case inside. Remove the cap from the top of the Collet die and push the mandrel, collet sleeve and collet out through the top of the die. Open the collet back up with a tapered punch or Phillips screwdriver.

Collet Die Pressure Exertion

All of the sizing in the Collet die takes place at the very end of the stroke, when the ram/shell holder appears to bottom out against the base of the die. If you lean into the handle at this point, you will force the collet up into the die body, and cause the collet to squeeze the case neck down against the mandrel (the very end of which pops out the spent primer). About 25 lbs. of force is sufficient to resize most cases. If you are sitting in front of your press, just leaning your upper body weight into the lever is about right.

A good way to determine how much is necessary is to start the case into the die and feel the die remove the primer. Start using pressure and work up to what you think is about 25 lbs. Remove the case from the die and attempt to place the intended bullet in the case neck. If there is little or no resistance, repeat the process with slightly more pressure. When you have reached a point where there are vertical striation marks on the outside of the case neck or the intended bullet does not fit easily into the case neck, the correct amount of pressure has been achieved.