Have a Question?

December 2012

You can subscribe to this Newsletter if you sign up for an account with Titan Reloading.

CLICK HEAR TO REGISTER AN ACCOUNT

CLICK HERE To browse an archive of past newsletters.

DECEMBER 2012 NEWSLETTER

DECEMBER 2012 NEWSLETTER

MERRY CHRISTMAS TO ALL. May you and yours have a wonderful Holiday season filled with JOY and PEACE.

Robin and I have officially opened the Titan Reloading Showroom at 660 Grand Ave., Hartford, Wisconsin on November 15th. We still have some decorating to do but we are fully functional. The store hours are Monday-Friday 8:00 AM to 5:00 PM, Saturday 8:00 AM to 12:00 Noon with Evenings and Weekends by appointment. Feel free to call 1-262-244-7023 to setup a meeting. We live only two tenths of a mile away and would be happy to accommodate your schedule. Here are a few snapshots of the showroom for our friends who may never get this far north.

Last month I introduced the new Consistent Crimp Handle to our product line. I just want to point it out again because it truly is the greatest new reloading product to come out in a long time. Anyone looking for COMPLETE CONTROL over the neck sizing and crimping processes need look no farther. The Consistent Crimp will allow you to quantify the exact handle pressure you use, round after round. CHECK IT OUT HERE!

We are truly enjoying all the friends we have made through Titan Reloading and look forward to many more. Feel free to contact us. Service and Support is our top priority. As always, you will find many answers to questions in the "FAQ" and "Help Videos" areas of our website www.titanreloading.com

Dennis / Titan Reloading

FEATURED PRODUCT:

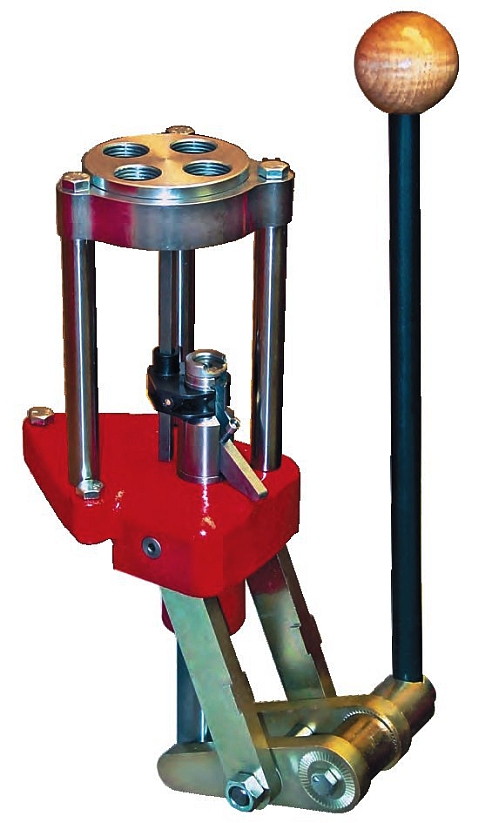

Lee Classic Turret Press

This press has all the features of the award-winning Turret Press with quality touches that make this the finest, most convenient press to own. The Classic Turret features the solid steel linkage of the Lee Classic Cast. Your first stroke of the hardwood gripped lever will convince you this is one, solid silky smooth press! The sturdy iron base shows its Classic Cast roots.

The long stroke allows rifle cases over three inches long to be loaded using the automatic index. Deactivate the Auto-Index and cases as long as the monster 50 BMG can be loaded. The rigid cast iron frame supports the ram with over 12 square inches of area. The industry's largest ram is drilled completely through to dispense primers in an attached clear PVC tube. Every primer is caught–guaranteed.

Instant change turrets are the same as the famous Lee Turret Press. The Classic Turret uses the new Lee Lever Primer System (LPS) and the Lee Safety Prime tool makes priming on the press a delight.

If you like to own the best, then treat yourself to the Lee Classic Turret. The finest reloading system made and it can be fitted with the new Consistent Crimp Handle for total control over neck sizing and crimping.

Specifications:

Press Type: Turret Press

Number of Stations: 4

Frame Material: Steel and Cast Iron

Frame Opening Size: 4-1/2"

Handle Location: Bottom Right or Left

Die Size Accepted: 7/8"-14 Threaded Dies

Ram Stroke: 3-1/2"

Ram Diameter: 1-1/8"

Priming Feature: Lever Prime

Number of Mounting Holes: 3

Mounting Hardware Included: No

INSIGHT OF THE MONTH:

Turret Press Indexing Explained

The square ratchet is both free to rotate inside the clamp and held fast by the clamp, depending on which direction the ram is moving. If you are lowering the press lever (raising the ram) you don't want the turret to rotate, so the square ratchet must be free to rotate inside the clamp. The friction between the square ratchet and the index rod causes the square ratchet to slide down to the bottom of the cavity inside the clamp, where it is free to rotate when it passes over the twist in the index rod. On the upswing of the press lever (as the ram goes down) the drag between the square ratchet and index rod causes the square ratchet to slide up to the top of the cavity inside the clamp, where the square ratchet fits into matching notches in the clamp which prevent the square ratchet from turning, so as it passes the twist in the index rod it turns the turret.

Included with the Deluxe and Classic Turret Presses is a spare black nylon ratchet. This installs inside the black auto index clamp on the steel ram. The square black ratchet rides on the 1/4"x 1/4" steel index rod. When removing the aluminum turret, be sure to raise the ram to disengage the square ratchet from the twisted part of the rod.

The nylon square ratchet that comes with the turret press is designed to properly index the press for 10s of thousands of rounds; however, an extra does comes with the press. This inexpensive part is made of nylon for two reasons with the first being that if the index rod is operated against the proper rotation, the nylon will fail before any damage occurs to any other part. The second is that they are inexpensive to produce and purchase.

The ratchet enables the indexing without "tweaking" or adjustment. The index rod may be removed and replaced at will without affecting the timing of the press. In the unlikely event that your press was received and not indexing correctly, the ratchet is not the reason and the issue is easily resolved by turret press index alignment.

The only reason the ratchet would be damaged is from forcing the index rod against that ratchet. This generally occurs when turrets are removed with the ram at the bottom of the stroke as the ratchet is engaged during the down stroke. When removing turrets, it is necessary to raise the ram about an inch or so.

A problem can ultimately affect indexing if the ratchet is excessively forced against the index rod, because the top portion of the ram, designed to rotate for another reason, would do so under these circumstances. Then, even with the ratchet replaced, the entire housing is off center. The proper alignment of the housing is completed by using the lever portion of the priming arm and aligning it with the two bumps on the base of the press

The nylon housing that holds the ratchet never needs to be opened other than to eventually replace the nylon ratchet. Remove the index rod, then the housing by removing the horizontal screw. Replace the ratchet remembering to place the flange in the downward position and reattach the nylon housing. This housing does nothing more than contain the ratchet. Do not over tighten the screw because the threads can be stripped.